20 мм ПМ микро сызыктуу кадамдык мотор 12VDC Туткундук жогорку тактыктагы сызыктуу мотор

Видео

Сүрөттөмө

SM20-020L-LINEAR SERIAL – бул жетектөөчү бурама менен тепкичтүү мотор. Ротор саат жебеси боюнча же саат жебесине каршы иштегенде, жетектөөчү бурама алдыга же артка жылат.

Тепкич моторунун кадам бурчу 7,5 градус, ал эми жетектөөчү аралыгы 0,6096 мм. Тепкич мотору бир кадам айланганда, жетектөөчү 0,0127 мм жылат.

Бул продукт компаниянын патенттелген продуктусу болуп саналат. Ал ички ротордун жана бураманын салыштырмалуу кыймылы аркылуу мотордун айлануусун сызыктуу кыймылга айландырат. Ал негизинен клапанды башкарууда, автоматтык баскычтарда, медициналык жабдууларда, текстиль машиналарында, роботтордо жана башка тиешелүү тармактарда колдонулат.

Ошол эле учурда, тышкы зым бөлүгү, адатта, туташтыруучу зым жана розетка кутучасы болуп саналат, ал эми жылаңач ийне кардардын муктаждыктарына ылайыкташтырылышы мүмкүн

Биздин команда тепкичтүү моторлорду долбоорлоо, иштеп чыгуу жана өндүрүү жаатында 10 жылдан ашык тажрыйбага ээ, ошондуктан биз кардарлардын өзгөчө муктаждыктарына ылайык продукцияны иштеп чыгууга жана көмөкчү дизайнга жетише алабыз!

Кардарлардын муктаждыктары - биздин аракетибиз, биз менен байланышуудан тартынбаңыз!

Параметрлер

| ПРОДУКЦИЯНЫН АТЫ | PM20 5v Сызыктуу кадамдык мотор |

| МОДЕЛЬ | VSM20L-048S-0508-32-01 |

| КАРШЫЛЫК | 13Ω±10% |

| Жыштыкты тартуу | 670PPS |

| МАРК ТАРТУУ | 600 г |

| индуктивдүүлүк | 4.5REF (мС) |

| Монтаждоочу апертура | φ3.7 мм (тешик аркылуу) |

| Октук бийиктик | 25,9 мм |

| Изоляция классы | Е классы |

| коргошун сыдырма | UL 1061 AWG26 |

| OEM жана ODM кызматы | БАР |

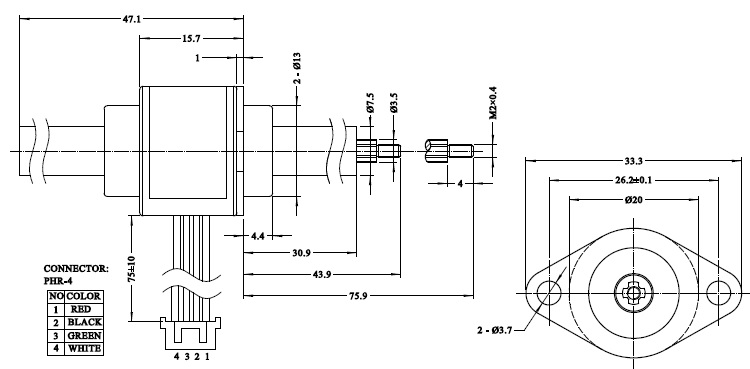

Дизайн чиймеси

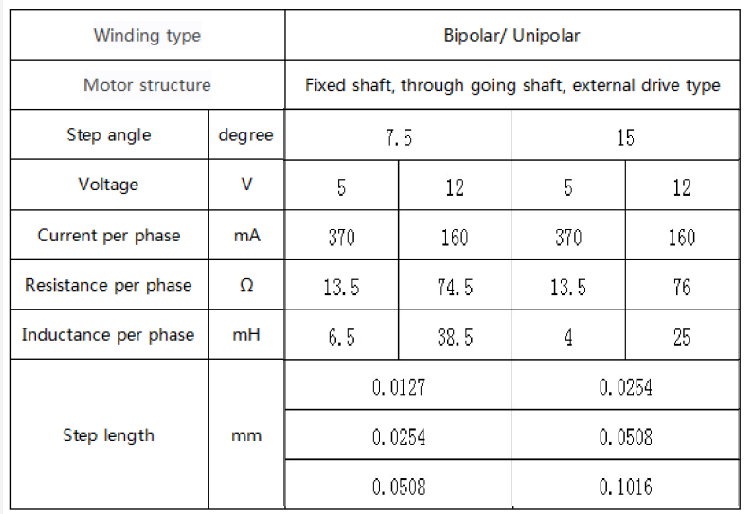

Мотордун параметрлери жана мүнөздөмөлөрү

ТУТКУНГА АЛЫНГАН

Туткунга алынбаган

Тышкы

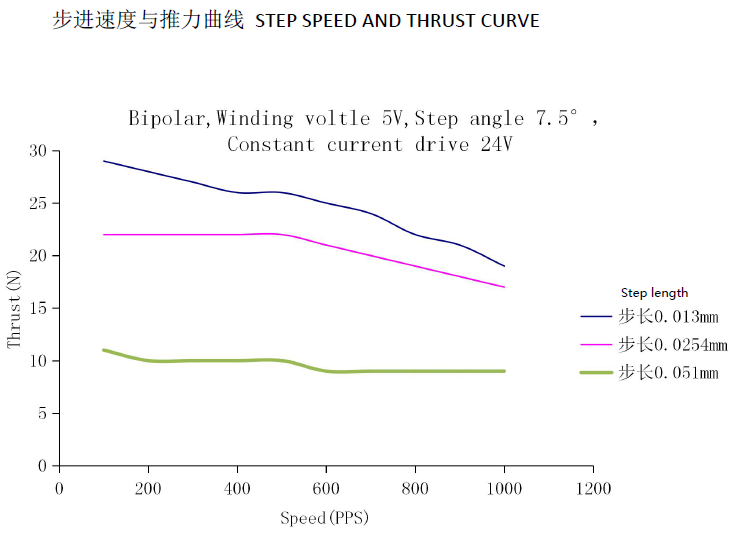

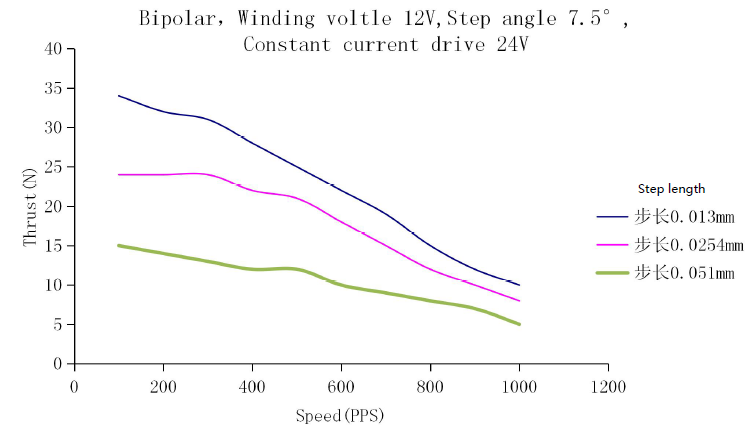

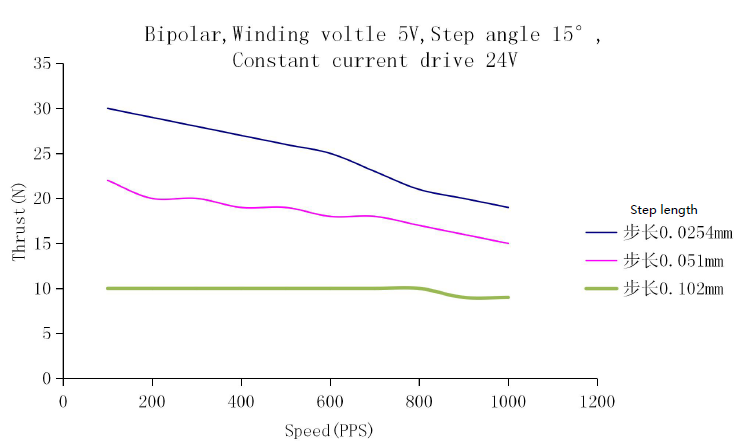

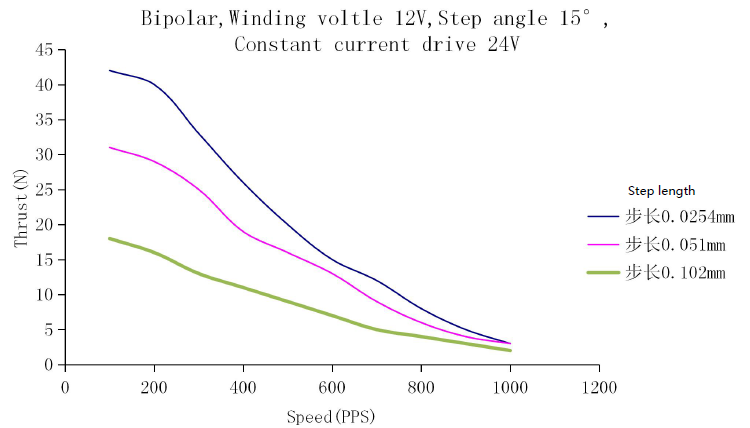

КАДАМ ЫЛДАМДЫГЫ ЖАНА ТҮРТҮҮ ИЙРИСИ

Колдонмо

Ыңгайлаштыруу кызматы

Мотор кадимки бурама жүрүшүн ыңгайлаштыра алат,

Туташтыргычтар жана розетка кутучалары кардардын талаптарына ылайыкташтырылышы мүмкүн

Бурама таякчасы гайканы да ыңгайлаштыра алат

Жеткирүү убактысы жана таңгактоо жөнүндө маалымат

Үлгүлөрдү жеткирүү убактысы:

Стандарттык моторлор кампада: 3 күндүн ичинде

Стандарттуу моторлор кампада жок: 15 күндүн ичинде

Ыңгайлаштырылган өнүмдөр: болжол менен 25 ~ 30 күн (ыңгайлаштыруунун татаалдыгына жараша)

Жаңы калыпты куруу убактысы: жалпысынан 45 күн

Массалык өндүрүш үчүн жеткирүү убактысы: заказдын санына жараша

Таңгактоо:

Үлгүлөр көбүк губкасына кагаз кутуча менен таңгакталып, экспресс аркылуу жөнөтүлөт

Массалык өндүрүштө моторлор сыртында тунук пленкасы бар гофрленген картондорго таңгакталган. (аба аркылуу жеткирүү)

Эгерде деңиз аркылуу жөнөтүлсө, продукт паллеттерге таңгакталат

Жеткирүү ыкмасы

Үлгүлөр жана аба аркылуу жеткирүү боюнча биз Fedex/TNT/UPS/DHL колдонобуз.(Экспресс-тейлөө үчүн 5 ~ 12 күн)

Деңиз аркылуу ташуу үчүн биз жеткирүү агентибизди колдонобуз жана Шанхай портунан жөнөтөбүз.(Деңиз аркылуу жеткирүү үчүн 45 ~ 70 күн)

Көп берилүүчү суроолор

1. Сиз өндүрүүчүсүзбү?

Ооба, биз өндүрүүчүбүз жана негизинен кадамдык моторлорду чыгарабыз.

2. Заводуңуз кайда жайгашкан? Заводуңузга барсак болобу?

Биздин завод Цзянсу провинциясынын Чанчжоу шаарында жайгашкан. Ооба, бизге келип кетүүгө кубанычтабыз.

3. Акысыз үлгүлөрдү бере аласызбы?

Жок, биз акысыз үлгүлөрдү бербейбиз. Кардарлар акысыз үлгүлөргө адилеттүү мамиле кылышпайт.

4. Жеткирүү акысын ким төлөйт? Мен жеткирүү эсебимди колдонсом болобу?

Кардарлар жеткирүү акысын төлөшөт. Биз сизге жеткирүү акысын айтып беребиз.

Эгер сизде жеткирүү ыкмасы арзаныраак/ыңгайлуураак деп ойлосоңуз, биз сиздин жеткирүү эсебиңизди колдоно алабыз.

5. Сизде MOQ деген эмне? Мен бир моторго заказ бере аламбы?

Бизде MOQ жок, жана сиз бир гана бөлүктөн турган үлгүгө заказ бере аласыз.

Бирок сыноо учурунда мотор бузулуп калса жана сизде запастык мотор болушу мүмкүн болсо, бир аз көбүрөөк буйрутма берүүнү сунуштайбыз.

6. Биз жаңы долбоорду иштеп чыгып жатабыз, сиз ыңгайлаштыруу кызматын көрсөтөсүзбү? Биз NDA келишимине кол коё алабызбы?

Бизде степпер мотор тармагында 20 жылдан ашык тажрыйба бар.

Биз көптөгөн долбоорлорду иштеп чыктык, биз дизайн чиймесинен баштап өндүрүшкө чейин толук комплектти ыңгайлаштырууну камсыздай алабыз.

Биз сиздин кадамдык мотор долбооруңуз боюнча бир нече кеңеш/сунуш бере аларыбызга ишенебиз.

Эгер сиз купуя маселелер боюнча тынчсызданып жатсаңыз, ооба, биз жашыруундук келишимине кол коё алабыз.

7. Драйверлерди сатасыздарбы? Аларды чыгарасыздарбы?

Ооба, биз драйверлерди сатабыз. Алар убактылуу үлгү сыноо үчүн гана ылайыктуу, массалык өндүрүшкө ылайыктуу эмес.

Биз драйверлерди чыгарбайбыз, биз бир гана кадамдык моторлорду чыгарабыз

Көп берилүүчү суроолор

1. Степпер моторунун ысыгын кантип азайтуу керек:

Жылуулуктун пайда болушун азайтуу жездин жана темирдин жоготуусун азайтуу болуп саналат. Жездин жоготуусун эки багытта азайтуу, каршылыкты жана токту азайтуу, бул мотор, эки фазалуу мотор параллель моторсуз моторду удаалаш колдоно алганда, мүмкүн болушунча кичинекей каршылыкты жана номиналдык токту тандоону талап кылат. Бирок бул көп учурда моменттин жана жогорку ылдамдыктын талаптарына карама-каршы келет. Тандалган мотор үчүн жетектин автоматтык жарым токту башкаруу функциясы жана оффлайн функциясы толук колдонулушу керек, биринчиси мотор тынч турганда токту автоматтык түрдө азайтат, ал эми экинчиси жөн гана токту өчүрөт. Мындан тышкары, бөлүнгөн жетек, токтун толкун формасы синусоидага жакын болгондуктан, гармоникалар азыраак болгондуктан, мотордун жылышы да аз болот. Темирдин жоготуусун азайтуунун бир нече жолу бар жана чыңалуу деңгээли ага байланыштуу. Жогорку чыңалуу менен иштеген мотор жогорку ылдамдыктагы мүнөздөмөлөрдүн жогорулашына алып келсе да, жылуулуктун пайда болушун да жогорулатат. Андыктан, жогорку ылдамдыкты, жылмакайлыкты жана жылуулукту, ызы-чууну жана башка көрсөткүчтөрдү эске алуу менен, жетектин чыңалуу деңгээлин туура тандашыбыз керек.

2. Степпер моторунун принциби:

Степпер моторунун ылдамдыгы драйвер менен башкарылат, ал эми контроллердеги сигнал генератору импульстук сигналды пайда кылат. Жөнөтүлгөн импульстук сигналдын жыштыгын башкаруу менен, мотор импульстук сигналды алганда бир кадам жылат (биз бүтүндөй кадамдык жетекти гана карайбыз), сиз мотордун ылдамдыгын башкара аласыз.

3. Кадамдык мотордун ылдамдыгына кандай факторлор таасир этет?

Степпер моторунун ылдамдыгы айдоочунун жыштыгы, тепкич моторунун кадам бурчу жана редуктор менен аныкталат.